Before getting into the actual Product lifecycle management software – PLM, let’s look into a few basics!

When you think about the journey of a product, from the initial idea to its launch and eventual retirement, it’s clear that managing this process efficiently is crucial. This is where Product Lifecycle Management (PLM) comes into play. PLM is a strategic approach that helps you oversee every phase of a product’s life, ensuring that each step is optimized for efficiency, cost-effectiveness, and innovation.

By using PLM, you can streamline the development process, reduce time-to-market, and ensure that your product meets both regulatory requirements and customer expectations. But how does PLM software work, and why is it so essential in today’s fast-paced, competitive markets? Let’s dive deeper into the world of PLM to find out.

Definition of Product Lifecycle Management

Product Lifecycle Management (PLM) is a comprehensive system that manages all aspects of a product’s life cycle, from initial concept and design through production, service, and eventual disposal or recycling. PLM integrates people, processes, business systems, and information to create a cohesive and streamlined process. Essentially, PLM is about managing product data, workflows, and decision-making processes throughout the product’s entire lifecycle.

By implementing PLM, you’re not just managing the physical aspects of a product but also the digital data associated with it. This includes everything from design files and material specifications to manufacturing processes and customer feedback. In essence, PLM serves as the backbone of a product’s journey, ensuring that every piece of information is accessible and up-to-date for all stakeholders involved.

History of PLM – from CAD to PLM

To truly appreciate the value of PLM, it’s essential to understand its history and how it has evolved over the years. The concept of managing product data isn’t new; it dates back to the industrial revolution, when manufacturers began to realize the importance of standardizing processes and documentation. However, the term “Product Lifecycle Management” didn’t emerge until the late 20th century.

In the 1970s and 1990s, as computer-aided design (CAD) and manufacturing (CAM) technologies advanced, companies needed a way to manage the vast amounts of data these systems generated. This led to the development of Product Data Management (PDM) systems, which were the precursors to modern PLM solutions. PDM systems focused on managing and controlling product data, but they lacked the comprehensive scope needed to oversee the entire product lifecycle.

As technology continued to evolve, so did the need for a more integrated approach. By the early 2000s, PLM had emerged as a distinct discipline, encompassing not only PDM but also other critical aspects of product development, such as collaboration, project management, and supply chain integration. Today, PLM is an indispensable tool for companies across various industries, from automotive and aerospace to consumer goods and electronics.

What Is PLM Software? – The Meaning

Imagine you’re trying to orchestrate a complex symphony where dozens of musicians need to play in perfect harmony. That’s essentially what managing your product’s lifecycle is like without proper software to help. Product Lifecycle Management software is that masterful conductor bringing order to chaos.

At its core, PLM software is a comprehensive platform that manages your product’s entire journey—from the initial spark of an idea through design, manufacturing, service, and eventually retirement. Think of it as your product’s digital twin, documenting and guiding every step of its existence.

You’re probably wondering, “Do I really need another software system?” If you’ve ever struggled with scattered product information, miscommunications between teams, or missed deadlines, then the answer might be yes. PLM software isn’t just another tool—it’s a strategic approach to your product development and management.

Unlike other business systems that focus on specific functions (like CRM for your sales or ERP for your operations), PLM software specializes in the product itself. It creates a central hub where everyone in your organization—designers, engineers, marketers, suppliers, and executives—can access accurate, up-to-date information about your products.

The beauty of modern PLM systems is their adaptability to your specific needs. Whether you’re producing fashion apparel, automotive components, or complex electronics, PLM software can be tailored to your specific industry requirements. Cloud-based software options have made these powerful tools accessible to businesses of all sizes, not just manufacturing giants.

What truly sets PLM apart is its holistic approach to your product data. Rather than optimizing individual stages in isolation, it connects every phase of your product lifecycle, creating a continuous feedback loop that drives improvement. When your customer suggests a feature improvement, that information flows back to your design team seamlessly. When your manufacturing discovers a more efficient process, that knowledge is preserved for your future products.

Today, markets are running too hectic, where product lifecycles are shorter than ever, having a system that streamlines your development, reduces your errors, and accelerates your time-to-market isn’t just convenient—it’s essential for staying competitive. As you explore deeper in this article, you’ll discover how the PLM platform can transform your product development process and deliver tangible business benefits.

PLM software also integrates with other enterprise systems, such as Enterprise Resource Planning (ERP) and Customer Relationship Management (CRM) systems, to provide a holistic view of your product’s lifecycle. This integration allows you to make more informed decisions, optimize processes, and ultimately deliver better products to your customers.

How Does a PLM System Work?

Ever wondered what happens behind the scenes when you implement a PLM system in your business? Let’s pull back the curtain on how these powerful platforms actually function in your real-world environment.

At its foundation, your PLM system creates what industry experts call a “single source of truth” for all your product-related information. Imagine replacing your scattered spreadsheets, isolated email chains, and disconnected databases with one comprehensive ecosystem where everything lives together harmoniously. That’s the magic of PLM for your organization.

Data Management

Your system’s architecture typically revolves around centralized data management—storing everything from your initial sketches and CAD models to your material specifications, testing results, and compliance documentation. When your engineer updates a component specification in Singapore, your colleague in Chicago sees that change immediately. This real-time synchronization eliminates those painful version control issues that plague your traditional processes.

Process Management

But your PLM isn’t just a sophisticated filing cabinet. It actively manages your workflows and processes throughout your product’s journey. When your design reaches a certain stage, the system automatically routes it to your appropriate stakeholders for review. When your testing reveals an issue, the platform triggers notification protocols, ensuring your right team members address it promptly. These automated workflows dramatically reduce bottlenecks that typically slow your development.

Collaboration

What truly sets your modern PLM system apart is its collaborative infrastructure. It creates virtual spaces where your cross-functional teams can communicate, share insights, and solve problems together regardless of physical location. You’ll witness your design teams and manufacturing partners collaborate on complex issues in minutes that previously would have required days of back-and-forth emails and calls.

Integration

The integration capabilities of your product lifecycle management system extend its value exponentially. By connecting with your ERP system for resource planning, your CAD tools for design, and your CRM platforms for customer insights, PLM creates a comprehensive digital thread that connects every aspect of your product’s existence.

Analytics

Perhaps most valuable is the analytical engine within your sophisticated PLM platform. Your system doesn’t just store data—it transforms it into actionable insights for you. By analyzing patterns across your product lines, identifying bottlenecks in your development processes, or correlating your customer feedback with specific design elements, your PLM delivers intelligence that drives continuous improvement.

Understanding how your PLM works helps explain why it delivers such transformative results for your business—it’s not just another business system, but a fundamental reimagining of how product information flows through your organization.

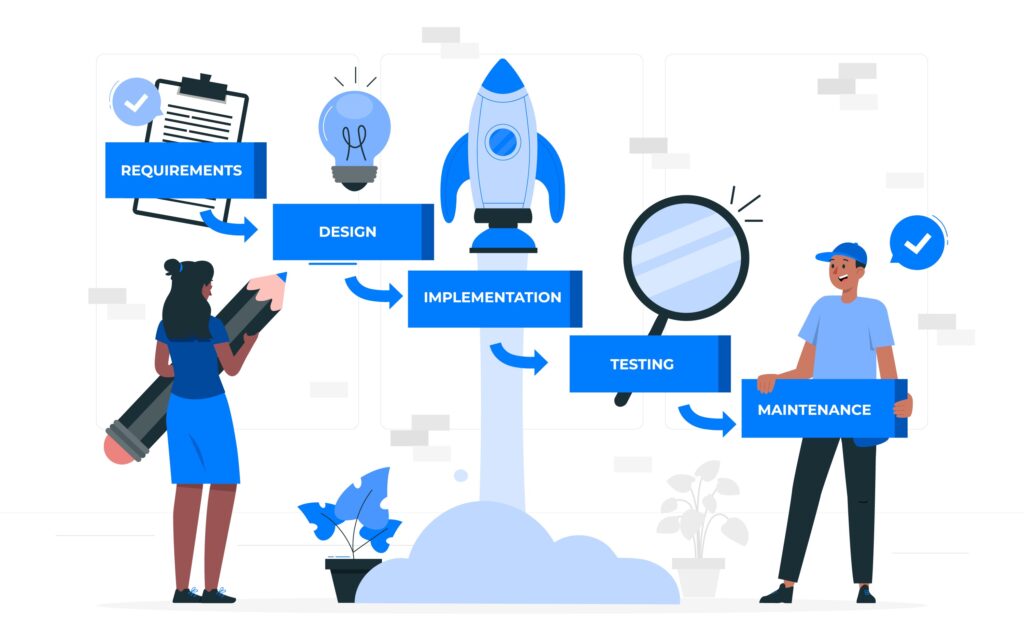

Key Phases of Product Lifecycle Management

Let’s walk through the journey a product takes from initial concept to launch, and how PLM software supports each critical phase along the way. Understanding this lifecycle gives you context for how these systems transform product development.

Concept

It all begins in your concept phase—that exciting moment when possibility is unlimited. Here, your PLM system captures and organizes your initial ideas, market research, customer requirements, and competitive analyses. Rather than having your brilliant concepts scattered across presentation decks and meeting notes, PLM creates a structured repository where your ideas can be evaluated against strategic criteria. You could reduce your concept-to-approval timeline by 40% simply by implementing a standardized approach to this initial phase.

Design

Once your concept gets the green light, you enter the design phase where your ideas transform into detailed specifications. This is where your PLM truly shines, managing your CAD files, material selections, component specifications, and design iterations. The system tracks every version change you make, maintains relationships between your components, and ensures your design standards are consistently applied. Most importantly, it enables your collaborative design reviews where stakeholders across your departments can provide early input—preventing those costly late-stage changes that occur when your manufacturing discovers a design can’t be produced efficiently.

Development

Your development phase is where designs become reality through your prototyping, testing, and refinement processes. Your PLM software manages test protocols, captures your results, and facilitates your critical decisions about what needs to be modified before production. You could reduce your development iterations by 60% by creating a structured approach to testing and validation.

Production

As you move into production, your PLM bridges the gap between your engineering and manufacturing teams, ensuring that your designs are optimized for efficient production. The system manages your bills of materials, production specifications, and quality control parameters. This seamless handoff eliminates the traditionally painful transition from development to manufacturing that often results in delays and quality issues.

Launch

When your product launches, your PLM system continues providing value by managing your marketing assets, sales collateral, training materials, and customer feedback. Later, it supports your service and maintenance operations by providing technicians with accurate product information. Finally, it manages your end-of-life processes like discontinuation, replacement strategies, and proper disposal or recycling methods.

Service and Support

Once the product is launched, you’ll need to provide ongoing service and support. This includes everything from managing warranties and repairs to gathering customer feedback and conducting product updates. PLM software helps you manage these processes by centralizing data, facilitating collaboration, and ensuring that all stakeholders have access to the information they need.

End of Life

Finally, the product will eventually reach the end of its lifecycle. This phase involves managing product recalls, recycling, and disposal. PLM software helps you manage this process by ensuring that all data is centralized, accessible, and up-to-date. What makes PLM solutions so powerful is this continuous, connected approach across every phase—creating institutional knowledge that improves each new product iteration.

Functions & Components of PLM Software

Let’s have a heart-to-heart about what PLM software actually does for your business in the real world. If you’ve ever felt overwhelmed juggling your product data across multiple systems or struggled to keep everyone on the same page, you’re not alone—and that’s exactly where PLM shines for you.

At its foundation, PLM software serves as your product’s complete digital headquarters. Remember that design change from six months ago? Or which supplier provides that specific component for your product? PLM keeps track of all this information in one accessible place, creating what industry experts call “a single source of truth” for your product data.

Team Collaboration

Design and development is where the magic begins for your team. Your creative staff can collaborate in real-time, regardless of whether they’re across the hall or across the globe. Your designers and engineers can share CAD files, specifications, and iterations without the dreaded “which version are we using?” confusion. This collaboration doesn’t just save your time—it sparks innovation as diverse perspectives merge to solve your problems.

Supply Chain Management

Once your design is ready, PLM extends its reach into your supply chain management, helping you identify your most reliable suppliers, track your material sourcing, and maintain optimal inventory levels. This integration is crucial—you could reduce your material costs by 15% simply by having better visibility into your supply chains through PLM.

Quality Control Management

Quality control becomes infinitely more manageable when your PLM software establishes clear standards and checkpoints throughout your production. Rather than discovering issues after manufacturing thousands of units, you can catch problems early in your process. For many companies, this capability alone justifies your PLM investment within the first year.

Regulatory Compliance and Documentation

As regulations grow increasingly complex across your industry, the compliance and documentation features of PLM software become invaluable to you. The system maintains your audit trails and ensures all your necessary certifications are current and properly documented—potentially saving you from costly fines or product recalls.

Data Analytics

Perhaps most exciting is how your PLM system leverages data analytics to inform your future decisions. By analyzing your performance metrics, customer feedback, and market trends, you gain insights that can guide your product improvements or inspire entirely new offerings. So, today everything is data-driven, this intelligence is the difference between leading your market and struggling to catch up.

Features of Product Lifecycle Management Software

When you’re evaluating PLM software for your business, understanding the core features is essential—these are the tools that will transform how your team works day-to-day. Let’s break down what makes PLM systems so powerful for your specific needs.

Data Management

Centralized data management is the heart of any PLM system you’ll implement—think of it as creating a digital “home” for everything related to your products. Instead of hunting through your shared drives, email attachments, or worse, someone’s personal computer, all your product specifications, design files, test results, and documentation live in one accessible location. This isn’t just convenient; it fundamentally changes how your teams interact with information. Finding the right information used to consume about 30% of your week—now it takes minutes.

Real-time Collaboration

The collaboration capabilities of modern PLM systems break down your traditional departmental barriers. Your engineering, manufacturing, marketing, and sales teams all work from the same platform, seeing updates in real-time. This transparent communication prevents those all-too-common scenarios where your marketing team describes features that your engineering team changed months ago, or your sales team promises delivery timelines that your manufacturing team knows are impossible. PLM creates an environment where everyone in your organization speaks the same language about product details.

Change Management

Change management might sound boring, but it’s where PLM software truly shines in preventing your costly mistakes. Every product modification you make, no matter how small, triggers notifications to your affected team members and creates a documented trail of who requested the change, who approved it, and when it was implemented. This systematic approach eliminates the “I didn’t know about that change” problem that plagues your product development. For regulated industries like medical devices or automotive, this feature isn’t just helpful—it’s essential for your compliance.

Compliance Management

Speaking of regulations, your PLM’s compliance management features automatically track and maintain the documentation required by various governing bodies. The system can alert you when your certifications are expiring, ensure your testing protocols meet current standards, and generate the reports you need during audits. This proactive approach to compliance prevents those panic-inducing moments when regulators come knocking and your documentation is scattered or incomplete.

These features work together as an integrated system rather than isolated tools in your business. When implemented thoughtfully, they create a smooth, continuous flow of information throughout your organization. The result is faster innovation, fewer errors, better products, and ultimately, happier customers—which is what your product development is really all about.

Benefits of PLM Platform

Let’s talk about what matters most to you—the tangible benefits your business can expect after implementing PLM software. These aren’t just theoretical advantages; they’re the real-world impacts you’ll witness across your organization.

Improved Productivity

First up is increased productivity, which happens almost immediately after your adoption. Remember all those hours your team spends searching for files, recreating lost work, or clarifying confused communications? PLM eliminates these productivity drains for you. You’ll find your engineers save an average of 9 hours weekly—time previously lost to administrative tasks—allowing them to focus on actual innovation instead. Think about what your team could accomplish with an extra day each week dedicated to meaningful work rather than managing information chaos.

Effective Cost Management

The cost management benefits of PLM might surprise you with their scope. Beyond the obvious savings from reduced errors and rework, PLM creates opportunities for strategic cost optimization throughout your supply chain. With complete visibility into your materials, components, and suppliers, you can identify opportunities for standardization and bulk purchasing. You might discover you’re ordering essentially identical components from three different suppliers at three different price points—a costly redundancy you can quickly eliminate after implementing PLM. These savings typically offset your implementation costs within the first 12-18 months.

Enhanced Data Integration

Data integration transforms how decisions are made across your organization. When everyone from your design to service departments accesses the same information simultaneously, your decisions become faster and more accurate. Your previous process might have been “making decisions by committee with incomplete information.” After your PLM implementation, you’ll find decision-making is “based on complete data available to all your stakeholders in real-time.” This transparency eliminates the friction that typically slows your innovation and responsiveness.

Efficient Product Streamlining

The accelerated time-to-market benefit can’t be overstated in the dynamic market for your products. By streamlining your entire product development cycle, PLM helps you beat competitors to market—often by months rather than days. This advantage translates directly to your revenue opportunities and market share. You could cut your development cycle by 35%, allowing you to release your product ahead of competitors who are targeting the same market segment.

Continuous improvement

Perhaps most importantly, PLM enhances your product quality by ensuring consistent standards and facilitating continuous improvement. When your customer feedback, quality issues, and enhancement requests are captured systematically, each of your product iterations becomes better than the last. This structured approach to quality management creates a virtuous cycle that builds your brand reputation and customer loyalty over time.

These benefits compound as your PLM system matures within your organization. What begins as operational improvement often evolves into strategic advantage, positioning your business to innovate faster, respond to market changes more effectively, and ultimately, outperform competitors who are still struggling with fragmented product information and disjointed processes.

Product Lifecycle Management (PLM) Software Use Cases

Wondering if PLM is relevant for your specific industry? Let’s explore some compelling real-world applications that demonstrate how this technology adapts to different business environments.

Automotive Industry

In the automotive industry, if you’re manufacturing vehicles, PLM becomes absolutely essential for managing mind-boggling complexity. Your modern vehicles contain up to 30,000 parts and must meet stringent safety, emissions, and performance standards across global markets. You can use PLM to manage your entire vehicle development process—from initial concept sketches to production specifications. When you need to recall a specific component, your PLM system can identify exactly which vehicles contain the affected part within minutes, potentially saving you millions in unnecessary repairs and immeasurably preserving your customer trust.

Aerospace and Defense

If you’re in aerospace, you face similar complexity with the added dimension of stringent regulatory requirements. You can use PLM to manage certification documentation for each component, ensuring complete traceability from your design specifications to testing results. When aviation authorities request your documentation during audits, information that once took weeks to compile is now available instantaneously. This capability doesn’t just save your time—it demonstrates the rigorous compliance that keeps your air travel safe.

Consumer Goods

If you produce consumer electronics, you can leverage PLM to manage incredibly rapid development cycles. You could reduce your product development timeline from 18 months to just 10 months by implementing PLM, allowing you to bring your new technology to market ahead of competitors. Your system would manage everything from your industrial design and component selection to software integration and packaging—ensuring that your complex ecosystem of suppliers stays perfectly synchronized throughout development.

Pharmaceuticals

In pharmaceuticals, your PLM system would maintain the exhaustive documentation required for your regulatory approval while managing your complex clinical trials and manufacturing processes. You could use your PLM system to ensure that every batch of your medication can be traced back to its raw ingredients, manufacturing conditions, and quality testing results—critical capabilities in your industry where patient safety is paramount.

Fashion and Apparel

Even if you’re in creative industries like fashion and apparel, you’ll benefit tremendously from PLM. You could use your system to manage seasonal collections across multiple markets, coordinating your designers, material suppliers, and contract manufacturers across three continents. Your PLM system would ensure that your fabric orders are optimized across product lines, reducing your waste and costs while maintaining your brand consistency.

These diverse examples demonstrate PLM’s remarkable versatility for your business—whether you’re making jet engines or jeans, the principles of effective product lifecycle management apply universally to your operations.

Choosing the Right PLM Platform

Finding the perfect PLM platform for your organization can feel overwhelming with so many options available. Let’s explore this critical decision with some practical advice based on helping dozens of companies make this choice.

Industry-Specific Features

First, clarify your specific requirements before evaluating any vendors. PLM systems vary dramatically in their focus—some excel at managing complex mechanical assemblies, while others specialize in formula-based products or fashion collections. Start by documenting your most critical processes and pain points, then prioritize features that directly address your challenges. Focus on your “must-haves” rather than getting distracted by impressive but ultimately unnecessary capabilities that add complexity without solving your specific problems.

Ease of Use

The implementation approach is equally important as the software itself for your organization. Some PLM solutions require extensive customization and IT resources, while others offer more configurable out-of-the-box functionality. Be realistic about your organization’s capacity for managing a complex implementation—sometimes, a slightly less feature-rich system that you can deploy quickly delivers more value than a comprehensive solution that takes years to fully implement in your business.

Scalability

User adoption ultimately determines your PLM success, so evaluate the user experience carefully. Schedule demonstrations with your actual users who will work with the system daily, not just your IT stakeholders or executives. The most powerful PLM system delivers zero value if your team avoids using it because of clunky interfaces or confusing workflows. You might choose a slightly less feature-rich solution specifically because its intuitive interface would drive higher adoption rates among your team—a decision that could prove incredibly wise when you achieve near-universal user adoption within months.

Integration Capabilities

Integration capabilities deserve your special attention during evaluation. Your PLM system will need to communicate with your existing enterprise systems like ERP, CAD tools, and possibly CRM platforms. Investigate whether vendors offer pre-built connectors for your critical systems, or whether costly custom integration will be required for your infrastructure. The smoothest implementations happen when your integration requirements are thoroughly understood upfront.

Vendor Support and Community

Finally, look beyond the technology to evaluate the vendor’s expertise in your specific industry. A partner who understands your business processes can provide invaluable guidance during your implementation and beyond. Ask potential vendors about their experience with companies similar to yours, request customer references in your industry, and evaluate their understanding of your specific challenges during presentations.

Remember that implementing PLM is not just a software project but a business transformation initiative for your organization. The right solution aligns with your strategic objectives, respects your organizational culture, and grows with your evolving needs.

How Does PLM Software Help a Business? A Real-life Example

You might be thinking, “This all sounds great in theory, but what about in practice?” Let me walk you through how PLM transforms your business operations with a real-world scenario that might feel familiar to you.

Picture this: You’re running a medium-sized fashion brand preparing your seasonal collection. Before implementing PLM, your process was a chaotic mix of spreadsheets, email chains, and physical samples shipped back and forth across continents. Your design changes were frequently missed, leading to production delays and inconsistent quality.

Sound familiar? This scenario plays out in businesses like yours across industries every day.

After adopting a fashion-specific PLM solution, you’ll see everything change. Your designers now work in a unified digital space where every sketch, material specification, and measurement is instantly available to your team members worldwide. When your designer in New York updates a pattern, your manufacturing partner in Vietnam sees the change immediately—no more confusion about which version is current.

The impact ripples throughout your organization. Your procurement teams gain visibility into upcoming material needs months in advance, allowing them to negotiate better prices with your suppliers. Your quality assurance managers set specific standards in the system, and your factory floor workers access detailed, up-to-date specifications through tablets, dramatically reducing your defect rates.

Your marketing and sales teams no longer wait for physical samples to start planning campaigns. They access digital assets directly from your PLM system, getting a head start on creating promotional materials. When your key retailer requests a minor modification to a popular style, the change is implemented and communicated to all your stakeholders within hours, not weeks.

The numbers will tell your story: You could reduce your sample iterations by 70%, cut your time-to-market by eight weeks, and decrease your material waste by 23% in just your first year using PLM. Beyond these measurable benefits, you’ll likely report something equally valuable—restored creativity. With administrative burdens reduced, your design team spends more time innovating rather than chasing information.

What’s particularly powerful about implementing PLM is how it fosters your sustainability initiatives. With better material tracking and reduced waste, your brand can make legitimate progress toward your environmental goals, creating authentic stories that resonate with your increasingly conscious consumers.

This fashion industry example demonstrates a universal truth: When you eliminate information silos and create transparent workflows through PLM, you don’t just become more efficient—you become more responsive, innovative, and competitive in your market.

Future of PLM Systems

As technology continues to evolve, so too does PLM. Where is PLM headed next? Let’s peek around the corner at emerging technologies that are set to revolutionize how we manage product lifecycles in the coming years.

Artificial Intelligence (AI)

Artificial intelligence is perhaps the most exciting frontier in PLM evolution for your organization. These technologies are transforming PLM from a passive data repository into an active partner in your product development. Imagine AI algorithms that can analyze thousands of your past design decisions to suggest improvements for your current project, or machine learning models that predict potential manufacturing issues before they occur in your production. You could implement AI-powered PLM that automatically flags design elements likely to cause quality issues based on your historical data—preventing problems before they even reach your production floor.

Internet of Things (IoT)

The Internet of Things (IoT) is creating a fundamental shift in how your products communicate throughout their lifecycle. Your connected products can now generate continuous streams of performance data that feed back into your PLM systems, creating what engineers call a “digital thread” from design through real-world usage. You could collect operating data from thousands of your machines worldwide, identifying patterns that inform your maintenance schedules and drive design improvements for your future models. This closed feedback loop can transform your product development from a linear process into a continuous improvement cycle.

Cloud-Based PLM

Cloud-based PLM solutions are democratizing access to these powerful tools for your business. What was once available only to large enterprises with substantial IT resources is now accessible to your mid-sized or even small business through subscription models. This accessibility can drive innovation across your industry as you leverage sophisticated product lifecycle management capabilities without massive upfront investments.

Digital Twin Technology

Perhaps most transformative for your product development is the emergence of digital twin technology—creating virtual replicas of your physical products that mirror their real-world counterparts in real-time. These digital twins enable unprecedented simulation capabilities, allowing your engineers to test thousands of scenarios virtually before committing to physical prototypes. You could reduce your physical prototyping costs by over 60% by implementing comprehensive digital twin technology within your PLM ecosystem.

Sustainability and Circular Economy

As sustainability becomes increasingly critical for your business, your PLM system can evolve to consider environmental impact throughout your product lifecycle. You can use PLM to track your carbon footprint, design for disassembly and recycling, and manage circular economy initiatives where your products are repeatedly refurbished rather than discarded.

These technological advancements aren’t just incremental improvements—they represent a fundamental reimagining of how your products are conceived, developed, manufactured, and managed throughout their useful lives. By embracing these emerging capabilities, you’ll find yourself with significant competitive advantages in increasingly complex global markets.

Conclusion

Product Lifecycle Management software is a powerful tool that can transform the way you manage product development. By providing a centralized platform for data management, process optimization, and collaboration, PLM helps you bring products to market faster, improve quality, and reduce costs. As technology continues to advance, the future of PLM looks even more promising, with innovations like AI, IoT, and digital twins set to take product lifecycle management to the next level.

Whether you’re in automotive, aerospace, consumer goods, or any other industry, PLM offers significant benefits that can help you stay competitive in today’s fast-paced market. By choosing the right PLM software and implementing it effectively, you can unlock new levels of efficiency, innovation, and success for your organization.

Product Lifecycle Management Software FAQs

To wrap up, here are answers to some frequently asked questions about PLM:

PLM is beneficial across a wide range of industries, including automotive, aerospace, consumer goods, pharmaceuticals, fashion, and electronics. Any industry that involves complex product development processes can benefit from PLM.

While both PLM and ERP manage different aspects of a business, PLM focuses specifically on the product lifecycle, from conception to disposal. ERP, on the other hand, manages broader business processes, including finance, HR, and supply chain management. PLM and ERP often work together to provide a comprehensive view of an organization’s operations.

Yes, PLM is not just for large enterprises. Small and medium-sized businesses can also benefit from PLM by improving efficiency, reducing costs, and accelerating time-to-market. There are scalable PLM solutions designed specifically for smaller organizations.

The time required to implement a PLM system varies depending on the complexity of your business processes and the specific PLM solution you choose. Implementation can take anywhere from a few months to over a year. It’s important to plan carefully and allocate sufficient resources to ensure a smooth implementation.

Common challenges include resistance to change, data migration issues, and the need for training. It’s crucial to have a clear implementation plan, involve key stakeholders early in the process, and provide adequate training to ensure successful adoption.